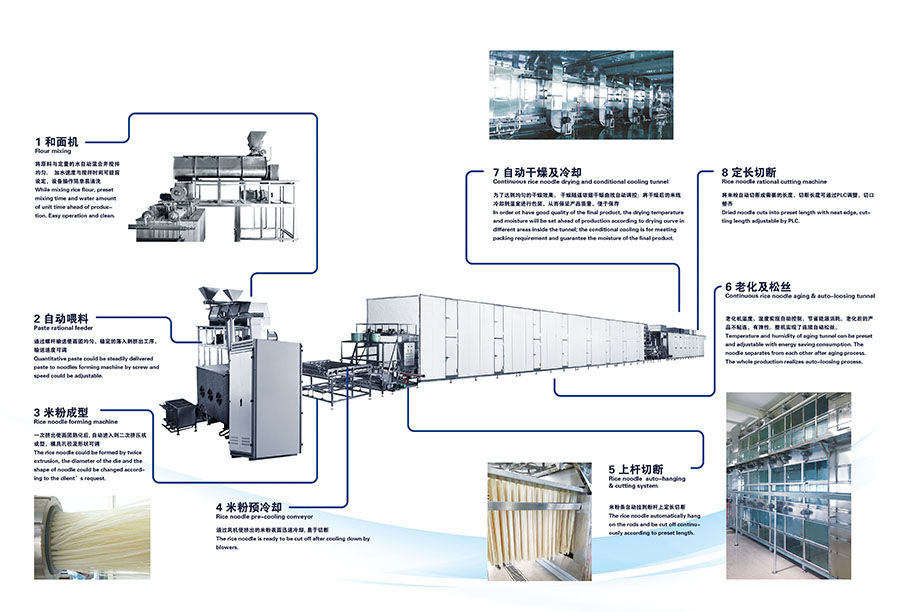

Automatic extruding stick rice noodle production line

The series of the automatic extruding stick rice noodle production line which is explored based on China Jiangxi rice noodle processing and Guilin rice vermicelli processing has realized the standard industrial production for its highly automation controlled from flour feeding to the final products. The operators only need to observe, monitor and adjust the equipments, which saves a lot of labors and reduces the product cost. In order to guarantee the high quality of the products and achieves industrialized production, the production line is controlled by scored of frequency conversion speed regulator which can adjust technical parameters of temperature, speed and pressure for each unit.

The noodle tastes firm and smooth both for boiling and cooking, diameter of the noodle is adjustable from 1.0mm to 1.6mm, the suitable raw material is kinds of rice or compound rice flours.

Main features

1. In order to meet the different clients requirement for the production, there are several capacity for choice, the biggest capacity is 1000 kg per hour

2. Adopt the closed production design, the operators only to observe, monitor and adjust the related data and equipments;

3. Meet international food hygiene standard, all the materials we adopt the stainless steel 304 and food grade materials with connect with food beside the special Alloy carbon steel for the extruder and templates; The pipes adopt quick connection for cleaning and maintenance;

4. Highly automation controlled by the PLC and touch screen connect with each part of the whole production line and all the commands carried by the Ethernet for information exchange and control instead of the traditional buttons and meters gradually.

NO. | Model | Output24 hours Tons | Dimensiion (L*W*H) m | Compressed Air m3/min | Steam Consumption Kg/H | Water Consumption T/day | Operators each shift | Electriciity Power(Kw) |

| 1 | SNTRV4 | 4tons | 48*2.65*3.05 | 1 | 500 | 3/12 | 5 | 90 |

| 2 | SNTRV7 | 7tons | 57*2.65*3.05 | 1 | 700 | 4/12 | 5 | 130 |

| 3 | SNTRV15 | 15tons | 66*3.5*3.05 | 1.6 | 1200 | 7/20 | 7 | 215 |

| 4 | SNYRV24 | 24tons | 81*3.5*3.05 | 2 | 1600 | 9/30 | 10 | 235 |

While mixing the raw material, how much water adding and mixing time could be set ahead of production.Easy operation and cleaning.

The rice noodle could be formed by twice extrusion, the diameter of the die and the shape of noodle could be changed according to the client’s request.

The rice noodle is ready to be cut after blew out the water of its surface and cooled down by the blowers.

In order to get the rice noodle better texture and meet the demands of aging process conditions, the temperature and humidity of the aging tunnel can be preset and adjustable with energy saving consumption. The noodle could be flexible & auto-loosed after aging process.

In order to have good quality of the drying and storing, the drying temperature and humidity will be set ahead of production according to the drying curve; The conditional cooling could meet the packing requirement and guarantee the moisture of the final products.

Dried noodles could be cut into the fixed length according to requirement with neat cut, and length could be adjustable by PLC.