Automatic instant rice noodle production line

The series of the SNTNRS automatic instant rice noodle production line which is explored by our latest technique with extrusion non-expansion without deep fried is widely received as healthy instant food. Not only the single rice but also compound grains are suitable as the raw materials for the production, such as corn, millet, oat, soba, etc. The noodle tastes firm and smooth with balanced nutrition. In order to meet the different clients, there are more than ten kinds of capacity production lines for choice with waved block form and round noodle cake.

Main Features

1. The whole production line is highly controlled automatically from flour feeding to the final products, less manual operation. The operators only need to observe, monitor and adjust the equipments, which saves a lot of labors and reduces the product cost.

2. No need to manually loose noodles and weigh each paste since the vermicelli is tidy after extrusion, and the weight of each noodle cake is stable, as the whole processing is controlled and adjusted in advance.

3. The aging tunnel is adopted multiply-level with temperature and humidity controlled inside which improves the aging effect, shorten the time, and save the energy.

4. In order to realize the industrial standard production and insurance the quality of final products, there are tens of frequency converts installed for the whole production line for controlling the temperature, humidity, adjusting speed of running, and so on.

5. To meet the different groups of customer requirement, not only the rice but also the compound grains such as corn, millet, soba,etc are widely used as raw materials.

6. Different capacity and scale equipments meet the different clients requirement.

No. | Model | Output (24hours/ bags) | Daily Capacity (tons) | Dimersion (L*W*H) m | Air Compressed m3/min | Steam Consunption Kg/H | Water Consumption T/day | Operarors each shift | Electricity Power (Kw) |

| 1 | SNTNRS4 | 40000 | 2.8 | 55*2.25*4 | 0.6 | 330 | 2/6 | 7 | 90 |

| 2 | SNTNRS8 | 80000 | 5.8 | 56*2.65*4 | 0.6 | 500 | 3/10 | 7+ | 125 |

| 3 | SNTNRS16 | 160000 | 11.2 | 63*4.5*4 | 0.9 | 820 | 5/15 | 10+ | 235 |

| 4 | SNTNRS24 | 240000 | 16.8 | 79*3.05*4 | 1.2 | 1050 | 7/20 | 15+ | 330 |

| 5 | SNTNRS36 | 360000 | 25.2 | 90*3.05*4 | 1.5 | 1400 | 11/30 | 15+ | 450 |

| 6 | SNTNRC4 | 40000 | 2.8 | 55*3.2*3.5 | 0.6 | 330 | 2/6 | 7 | 90 |

| 7 | SNTNRC8 | 80000 | 5.8 | 57*3.2*4 | 0.6 | 500 | 3/10 | 7+ | 125 |

| 8 | SNTNRC16 | 160000 | 11.2 | 80*4.6*4 | 0.9 | 820 | 5/15 | 10+ | 235 |

| 9 | SNTNRC24 | 240000 | 16.8 | 80*6.5*4 | 1.2 | 1050 | 7/20 | 15+ | 330 |

| 10 | SNTNRC36 | 360000 | 25.2 | 110*6.5*4 | 1.5 | 1400 | 11/30 | 15+ | 450 |

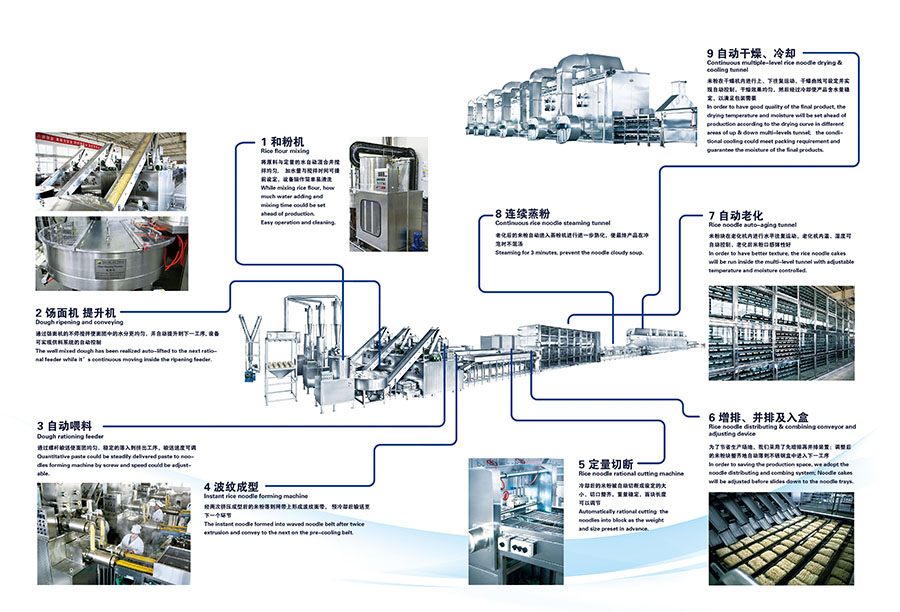

While mixing rice flour, how much water adding and mixing time could be set ahead of production.

Easy operation and cleaning.

Quantitative paste could be steadily delivered paste to noodles forming machine by screw and speed could be adjustable.

The instant noodle formed into waved noodle belt after twice extrusion and convey to the next on the pre-cooling belt.

Automatically rational cutting the noodles into block as the weight and size preset in advance.

In order to saving the production space, we adopt the noodle distributing and combing system; Noodle cakes will be adjusted before slides down to the noodle trays.

In order to have better texture, the rice noodle cakes will be run inside the multi-level tunnel with adjustable temperature and moisture controlled.

Steaming for 3 minutes, prevent the noodle cloudy soup.

In order to have good quality of the drying and storing, the drying temperature and humidity will be set ahead of production according to the drying curve in different areas of the up & down multi-levels tunnel; the conditional cooling could meet the packing requirement and guarantee the moisture of the final products.